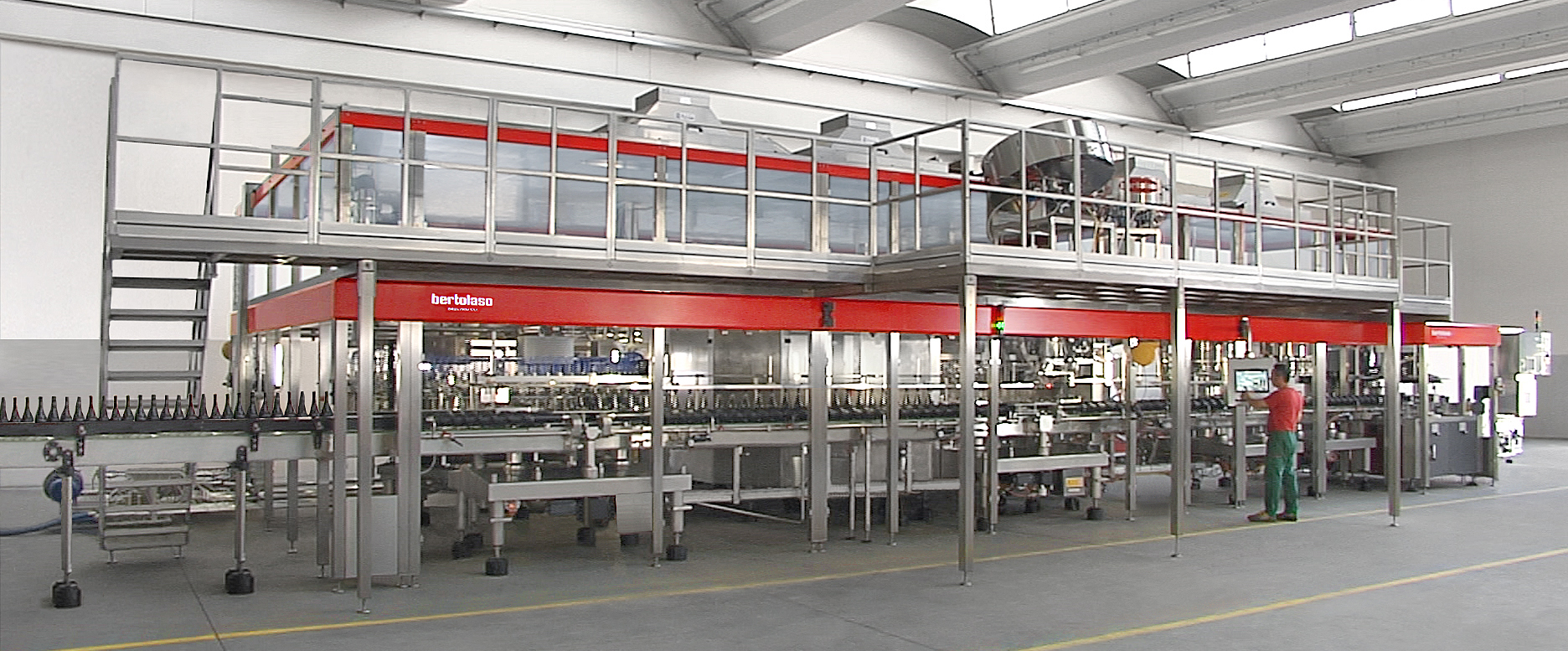

Integrated machines

Customized solutions to meet every bottling need

The Bertolaso monoblocs are not only machines locked together to form one unit but highly specialized and efficient integrated production systems : the particular attention given to every specific production need of every single user is changed into customized technical solutions to meet every requirements.

No matter if it is a simple rinser-filler-corker bloc or a complex system incorporating also wirehooder, capsuler and labeler, the operation logic is always simple and immediate thanks to the modern and functional operator panels and to the perfect mechanical and software integration of the different modules.

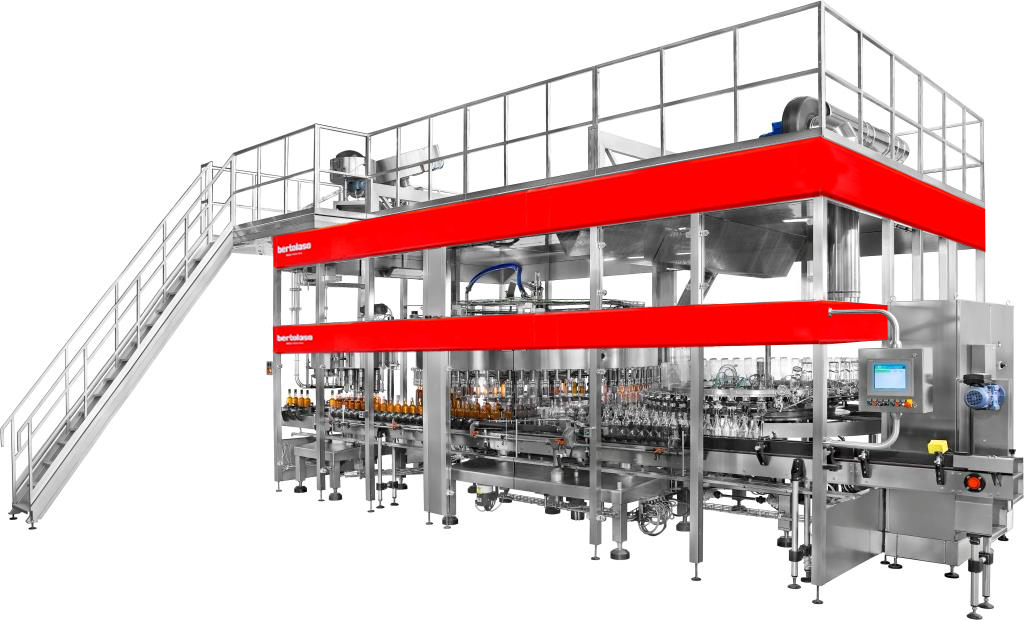

Unibloc 48/64/9/8

Unibloc 48/64/9/8

Electro-pneumatic filling bloc with rinser/filler/corker/screw capper for still and sparkling wines.

The bloc is capable to reach a speed of 12.000 bph on 750 ml bottles with still wine and 9.000 bph on 750 ml bottles with sparkling wine.

Wine unibloc

Wine unibloc

Unibloc for rinsing, filling and double closing (cork and/or screw cap) for still wines without the presence of oxygen. The unit can reach a speed up to 10.000 bph with 750 ml bottles.

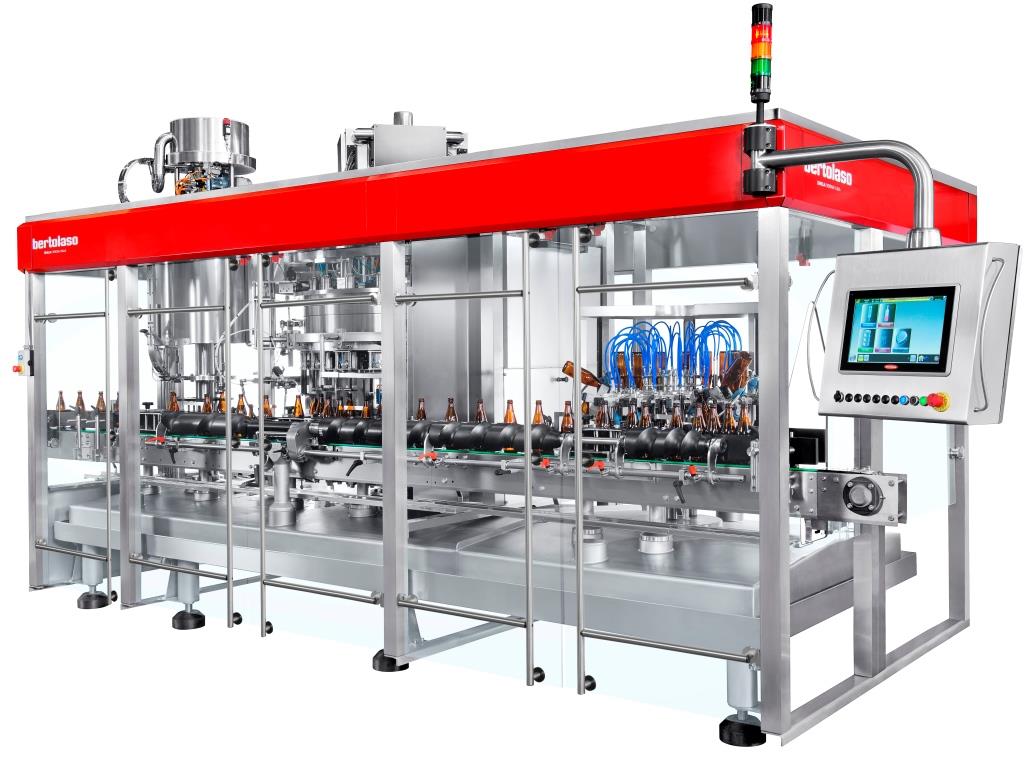

Unibloc 16/18/3

Unibloc 16/18/3

Electro-pneumatic unibloc for rinsing, filling and capping specifically designed for beer bottling. The machine embeds dedicated solutions such as high-pressure water jet for bottle neck gas saturation between filling and capping. The unit reaches 5000 bph with a 330 ml bottle.

Spirits unibloc

Spirits unibloc

Unibloc for rinsing, filling and capping, specifically designed for the spirits industry. The unit can reach a speed up to 11.000 bph with 750 ml shaped bottles.

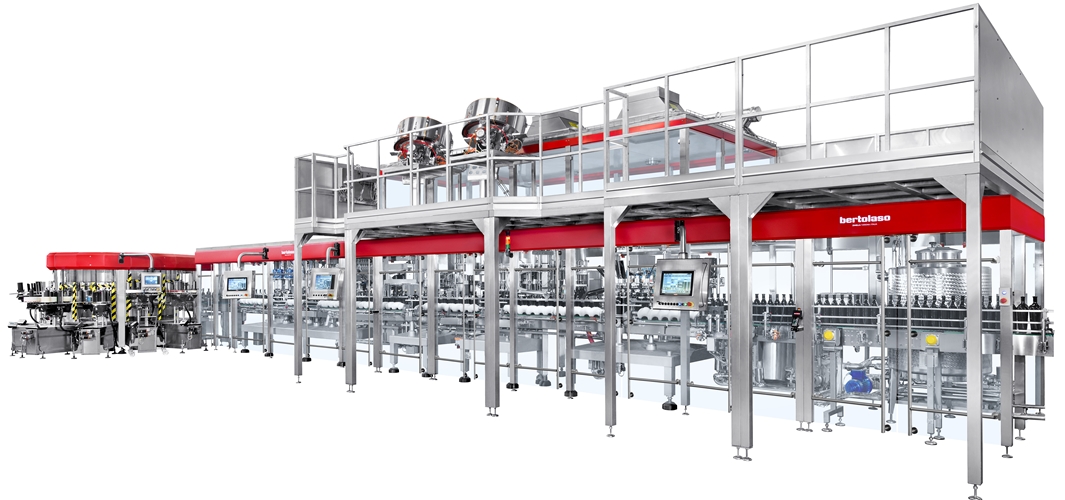

Unibloc 72/126/16/16/24

72/126/16/16/24 Unibloc

Electro-pneumatic unibloc for rinsing, filling, double closing and wirehooding still and sparkling wine bottles. This machine is capable to reach a speed of 21.000 bph with slightly sparkling wine and 18.000 bph with sparkling wine based on 750 ml bottle.

Some more features:

-The rinsing, filling and closing phases are performed with dedicated technologies for still and sparkling wines resulting from our technological study and long experience in the wine industry

-All the phases of the filling process are managed by the filler through an electro-pneumatic control, so that they can be optimized and memorized

-The machine sanitation is completely automatic through the use of an external CIP unit. Also the external surface of the machine is sanitized, including the bottle change parts

-Reduced set-up times for format changeovers because the machine adjusts itself automatically based on pre-determined production parameters. In addition, the adjustable starwheels allow to run by an easy adjustment different bottle sizes with a broader range of diameters.

-The frames are in stainless steel, with reduced dimensions and high inclination to ensure easy sanitation and access to the machine

-The main motors are brushless to ensure the best efficiency in the drive, noise reduction of flexibility of use