Fillers

The Bertolaso high-capacity solutions for wines are worldwide known for their innovation and quality.

The same expertise in the automatic filling level control is extended to all the sectors. A goal: never alter the liquid properties.

Our different typologies

Fillers

Gravity and/or Low vacuum

There are several types of gravity and/or low vacuum fillers depending on the application area of the machine. Our R&D office has developed a series of specific applications to optimize the solutions required for each area: wine, spirits, juices and drinks, water.

In addition to the traditional gravity and low vacuum fillers, Gruppo Bertolaso has developed a range of so-called “no-oxygen” machines to be specifically used in the wine industry.

The most important features of this “no-oxygen” filling system are summarized on a newly conceived filler with a filling valve manufactured with the best technologies in the market and based on the great experience gained by Bertolaso during more than 100 years of history. In this way, it is possible to fill still wine and slightly sparkling wines with a filler capable to perform a filling cycle similar to that of the counter pressure fillers but with significantly lower costs.

Today the market demand is to ensure:

- maximum stability of the filled product and protection

- primarily from oxidation

- protection of wine from microbiological contamination

- protection of wine from any other type of contaminant

Oxidation is an important factor in the food packaging industry: it may result in a decline of the organoleptic properties and shelf-life reduction. Moreover, as result of oxidation protection of the products during filling their quality and duration is improved, whilst the quantity of necessary antiossidants is reduced.This is particularly important for the delicate and fine wines, whose particular characteristics are the result of as delicate balance that can be easily altered by the industrial packaging processes.

All of this has led Gruppo Bertolaso to develop a new line of no-oxygen filling systems capable of performing the entire bottling cycle – from wine treatment to bottle rinsing,filling and corking – avoiding product and ambient air contact (“no-oxygen”), and protecting it from any type of contamination.

Fillers

Isobaric

The isobaric filling systems developed by Bertolaso consist in machines manufactured according to the most advanced filling technologies that catch the user’s interest for their production flexibility and process quality.

The most important features of the isobaric filling systems are summarized in a newly conceived isobaric filler with a filling valve manufactured with the best technologies in the market and based on the great experience gained by Bertolaso during more than 100 years of history; thanks to this, it is possible to fill sparkling, slightly sparkling and still wine.

With the Bertolaso isobaric filling systems, sparkling and slightly sparkling wines can be filled with optimized filling cycles reducing the dead time due to a multi-phase snifting.

Still wines can be filled with overpressure, thus improving the filling quality and reducing the energy consumption of the plant.

The isobaric filling systems are conceived to ensure a zero increase of the oxygen in the wine.

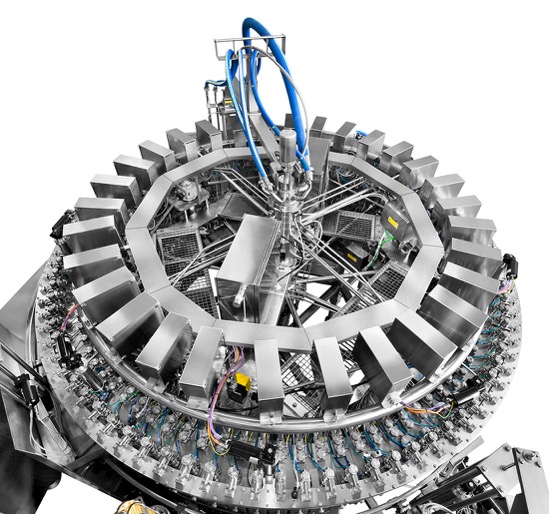

Elettra

The electropneumatic filler is a very flexible filler produced by Bertolaso, of great impact in the wine industry and with the best results in terms of performance. The project focuses on a newly conceived isobaric filling valve. The proposal of Gruppo Bertolaso is extremely ambitious: a filling machine capable of filling both still and sparkling wines, to work with reduced overpressure to 0,3 bar, and with the possibility to separate the partially oxidized gases present in the bottle from the product inside the bowl. The machine ensures a zero increase of oxygen in the wine.A filling valve made of a simple pipe in Aisi 316 stainless steel goes through the inside of the bowl: this allows the maximum level of filler sanitation. The innovative solution permits to remove the gas contained in the bottle and to convey it outside the bowl, thus avoiding any contact of the product with the outside. Thanks to constant upgrades, Bertolaso is able to ensure and achieve the minimum oxygen pickup in every working condition. The high specific speed achieved with this innovative filling valve and its operative reliability are combined at the best and allow a constant production efficiency at the highest levels.

Fillers

Volumetric